Swing up stabilisers: Tier One contractors specific site entry requirements

Briefing note for FASSI customers / operators (updated 19/06/23)

Summary box

Tier One contractors have confirmed their acceptance criteria for lorry loaders with swing-up stabiliser legs. In this briefing note we explain what this means for FASSI customers / operators.

All FASSI cranes conform to the product design standard, BS EN 12999, which provides the means for loader cranes to comply with the essential health and safety requirements of the Machinery Directive 2006/42/EC. They are CE marked, legally compliant & when used in accordance with the manufacturers instructions, safe to use.

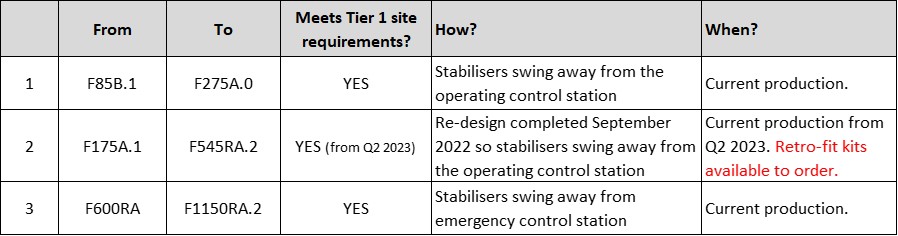

- The FASSI range from F85B.1 – F275A.0 meets the Tier 1 contractors specific site entry requirements because the stabilisers do not swing across the stabiliser control station & will qualify for a QR site entry code with no modification required.

- From Q2 2023 production the FASSI range from F175A.1 – F195A.1 & F245A – F545RA meets the Tier 1 contractors specific site entry requirements because the stabilisers have been redesigned to not swing across the stabiliser control station & will qualify for a QR site entry code with no modification required **.

- The FASSI range from F600RA – F1150RA meets the Tier 1 contractors specific site entry requirements because the stabilisers do not swing across the emergency control station & the remote control stabiliser operation meets the approval criteria. These cranes will qualify for a QR site entry code with no modification required.

The stabilisers on FASSI cranes swing away from the control station to meet the Tier 1 requirements without the need for additional monitoring systems & components / sensors. This has the additional benefit of always being operational even when the crane is excluded for recovery in a breakdown scenario.

** Cranes manufactured prior to Q2 2023 can be modified by our main dealers to not swing across the stabiliser control station to meet the Tier 1 contractors specific site entry requirements. FASSI UK has issued a service bulletin authorising this modification to be carried out together with parts kit prices (replacement rotating stabiliser supports & pipes). The work is chargeable to customers / operators who can order the kits from their supplying main dealer. Once the work is completed the crane will qualify for a QR site entry code.

ALLMI the trade body for the Lorry Loader industry has issued a Safety Alert and also created a Guidance Note and an E-Learning Module in conjunction with manufacturers and the Tier 1 group.

All cranes with Swing Up Stabilisers will require a QR code for the equipment to be allowed on site as well as proof that the operator has successfully passed the E-Learning Module or site entry will be refused.

Please follow the link to the ALLMI site: Swing-Up Stabilisers (allmi.com)

The HSE has also released a statement which can be found on the ALLMI website via this link: HSE Issues Supportive Statement (allmi.com)

Customers / operators whose cranes meet the Tier 1 site entry requirements can contact their supplying main dealer who will be able to register the crane and obtain / apply the QR code site entry sticker:

Alltruck Crane Repairs & Sales

Danny Smith

danny@alltruck.co.uk

Avon Crane & Commercial Repairs

Ben James

benjames@avoncrane.co.uk

Central Crane Technicians

Ben Draper

ben@centralcranetechnicians.co.uk

Kearns & Murtagh

Eddie Murtagh

eddiemurtagh@hotmail.co.uk

Macs Truck Sales

Craig Graham

craig@macstrucks.co.uk

The Crane Centre

Vince McHale

vince@cranecentre.co.uk

Walker Crane Services

Paul Nielson

pnielsen@walkercranes.co.uk